|

|

|

Latest News: Development of Large High-Power Mobile Solar Arrays

MEI is currently accelerating it's development of designs and manufacturing drawings for folding solar arrays which allow a large-scale PV generators to fold compactly into a small volume for ease of transport and storage, and can be quickly deployed into a 10-20 KW off-grid solar generator, or grid-tied power modules.

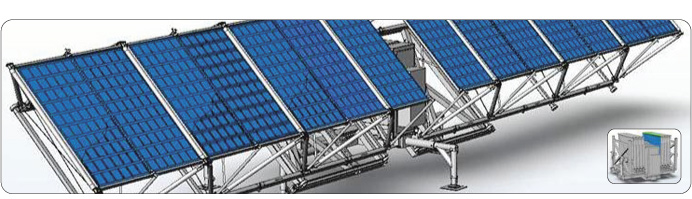

MEI’s unique structural support permits stacks of PV modules (panels) to be easily unfurled and then sun-oriented as desired. The array of panels rests on a simple truss structure which unfolds with the panels as shown below:

The above graphic depicts an 11 KW array deployed from a flat-bed carrier in support of a remote field project, followed by a photo of the initial hardware built by United Space Alliance (USA) at NASA-KSC, and a graphic that shows how a row of PV panels can fold compactly to 4-6% of the row length. USA was responsible for project management, system design, integration, fabrication and testing of the 5 KW prototype hardware. >>More...

The above graphic depicts an 11 KW array deployed from a flat-bed carrier in support of a remote field project, followed by a photo of the initial hardware built by United Space Alliance (USA) at NASA-KSC, and a graphic that shows how a row of PV panels can fold compactly to 4-6% of the row length. USA was responsible for project management, system design, integration, fabrication and testing of the 5 KW prototype hardware. >>More...

APRIL 2012: INTRODUCING NEW SOLAR ARRAY DESIGNS FOR 100-500 KW-CLASS MOBILE SYSTEMS FOR GRID-TIED AND OFF-GRID APPLICATIONS

With a new 22:1 folding ratio enabling efficient transport and handling of large solar arrays, 100 kw or more of PV capacity can be stowed in a 40 ft standard cargo box for ease of transport and deployment, with space for optional stowage of power handling modules. A typical configuration uses 4-6 pallet/skid-mounted PV arrays similar to the 36 and 54 module arrays seen below. They are internally rail-mounted for efficient load/unload, with provisions for rapid deployment. Alternatively, a standard 53 ft flatbed trailer will transport 180 KW for "plug-and-play" rapid deployment. In summary, applications of these new arrays include utility-scale power plants, microgrids, emergency management, electric vehicle (EV) charging, humanitarian deployments, and others.

We have begun product development engineering support to a new start-up company CPI-Technologies, LLC, in Cape Canaveral, Florida and have initiated discussions aimed at a joint venture for development of patent-pending truss-based solar arrays for a variety of applications including those cited above. A current focus is on large solar array modules for megawatt-size solar farms. These arrays are factory-preassembled and folded compactly to reduce field installation costs, with strong potential to significantly reduce overall Balance-of-System (BOS) costs, a major DOE goal. Our approach represents the potential for creation of new production jobs in Tennessee and Florida.

Merrifield Engineering is currently supporting demonstration of the NASA KSC portable solar generator prototype, which uses our prototype folding truss designs. In February, the technology was described at the 2012 Space Coast Energy Symposium, held at the Florida Solar Energy Center in Cocoa, Florida.

AUGUST 2011: MERRIFIELD ENGINEERING EXHIBIT AT TENNESSEE SOLARSOLUTIONS CONFERENCE IN NASHVILLE, TN

Merrifield Engineering was pleased to participate in the 2011 Tennessee SolarSolutions Conference with an exhibit of our capabilities in engineering and design of high power solar arrays for transportable rapid-deploy off-grid PV power systems. Highlighted was our existing design of deployable solar arrays for NASA Kennedy Space Center (see next section). The exhibit and presentations focused on Merrifield Engineering's innovative designs in which our patent-pending deployable truss structures enable the design of large PV arrays which can be folded compactly, transported easily, and readily deployed at a desired offgrid location.

The Nashville solar conference, which was sponsored by the Tennessee Solar Institute (TSI) and the Tennessee Valley Authority (TVA) had an overflow registration and was highly successful. The overall program, with links to the presentations can be found at here.

|

Merrifield Engineering, Inc. Exhibit Booth |

APRIL 2011: SOLAR GENERATOR TESTING AT NASA KENNEDY SPACE CENTER

In April, Merrifield Engineering assisted United Space Alliance in testing and deployment demonstrations of NASA-KSC's new portable twin-module solar generator. Performed near the Vehicle Assembly Building at the LC39 launch complex in Florida, it demonstrated clearly how the small 5'x6' footprint modules could quickly deploy 27 PV modules folded within four Merrifield Engineering P-trusses, with each expanding from 17.5 inches length to 21 ft length. The hardware is currently undergoing completion of electrical and battery integration/activation.

To learn more, check-out the article on NASA KSC's website.

Select an image for a closer look at the demonstration/test operations.

TRUSS DESIGN CONFIGURATIONS FOR PORTABLE SOLAR PV ARRAYS

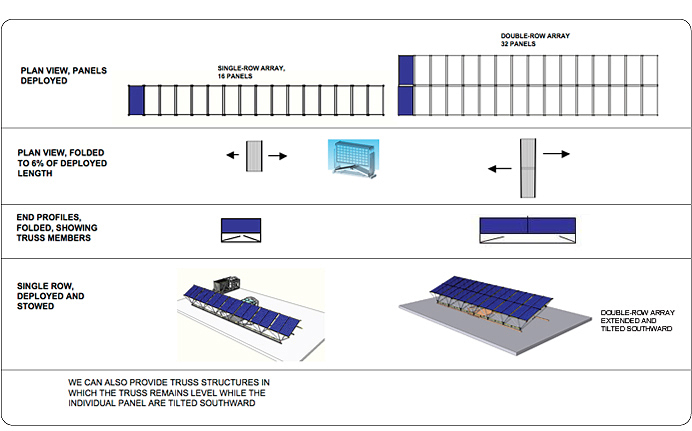

Our trusses can deploy multiple panels stowed in a series-hinged manner, as seen below. Shown are single and double row arrangements, each of which can stow compactly like vertically stacked panels. Two to four truss/panel arrays can be mounted on a single carrier pallet or trailer for total numbers exceeding 54 on a 6 ft x 12 ft pallet or trailer bed.

MOUNTING OPTIONS FOR PV/TRUSS ARRAYS AND ELECTRONICS/BATTERIES

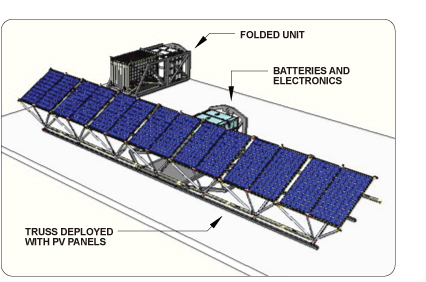

We have several standard mounting options, or they can be customer specified. Standard configurations include flat pallet mounting for ground-level deployment, flatbed trailer mounting with off-load capability, or enclosed trailer with side-mounted arrays. The simplest mounting for minimum retracted volume is depicted below for a 14-panel single-row array, with key components noted. This small array can be sized upward to deploy a 54 PV module array.

|

Note: The complete folded/stowed unit can be designed for handling by several means depending on the intended deploy site and handling equipment available. A back-up generator unit is not shown here and can either be on the pallet or a conventional stand-alone with cable connection. |

HIGH POWER PORTABLE SOLAR PV ARRAYS

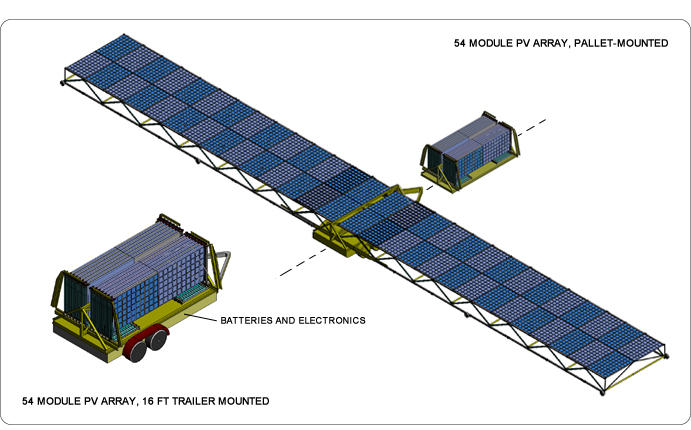

MEI has just completed a product design study of a new class of highly-compact mobile solar PV arrays which can deploy 54 or more solar modules, yet retracts onto a 6 ft x 12 ft pallet for transport by a 16 ft trailer or suitable carrier. Using 315 watt modules, peak power is 16.5 KW. The 54-module size exceeds currently available mobile solar generators while having much smaller stowage volume - smaller than trailer mounted systems that deploy 24 modules, and smaller than 48 module units requiring 48 ft trailers, or 36 module units requiring 30 ft trailers. Principal design options include:

- Size range of 36 to 54+ modules on a 6 ft x 12 ft pallet, or 24 to 30 modules on a 6 ft x 8 ft pallet.

- Transport by trailer, tilt-bed car-carrier or equivalent, or standard shipping container

- The off-grid battery/electronics unit can be pallet mounted or configured as a separate portable unit.

- Although designed for preferred sun orientation of 0 -12 degrees, favoring summer/spring-fall operation, sun tilt capability of up to 20 degrees can be provided.

Two principal advantages of our compact stowage design is the use of smaller lower-cost trailers with reduced energy intensive manufacturing. The use of simple low-profile mounting pallets (or skids) provides stowage and transport cost savings. For severe wind conditions all panels can be tightly retracted. For air or sea transport the compact packaging provides significant cost advantages.

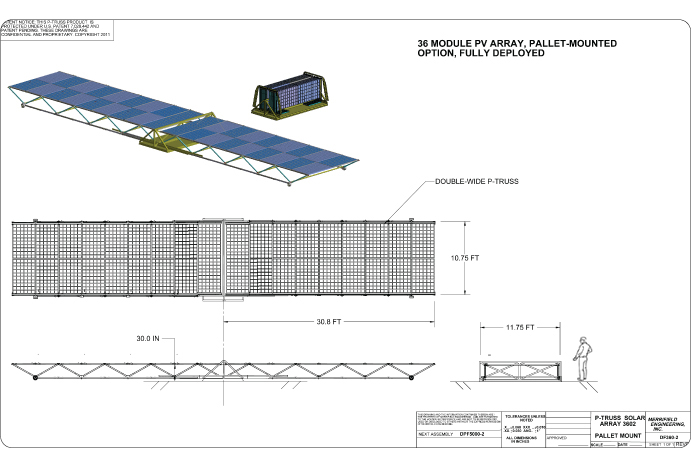

36 PV MODULE PALLET-MOUNTED ARRAY

Below is a 36 PV module pallet/skid mounted portable solar array with four 9-module truss arrays, which is readily transported by tilt-bed car carrier or similar means, and can be trailer mounted. It uses Merrifield Engineering’s patent-pending P-truss design.

The pallet size is 6 ft x 12 ft x 3 in thick and can also be transported within a standard 20 ft cargo box half-height or full- height. For ground placement as shown, the arrays are extended 32 ft using end-mounted wheels. Extension of all 4 arrays is planned to take approx 15 minutes.

The battery/electronics unit can be transported as a separate module and connected to the PV arrays for a peak solar generation capacity of 10 KW or more. Tilting of the pallet for increased power output can be accomplished with two electrical actuators mounted to the pallet.

The modular nature of the design permits upsizing to 15-16 KW with the same size pallet, and double-wide trusses can be used as seen in the next section.

36 MODULE CONFIGURATION, PALLET-MOUNTED

The configuration layout below shows principal dimensions for a typical 36 module system on a 6 ft x 12 ft structural pallet (or skid). It uses a double-wide P-truss design. The iso views indicate how the 62 ft array is readily stowed on the pallet for transport by suitable means such as a tilt-bed carrier or hook loader, and can also be shipped in a standard cargo container. If southward sun tilting is desired, electric lift actuators can be provided.

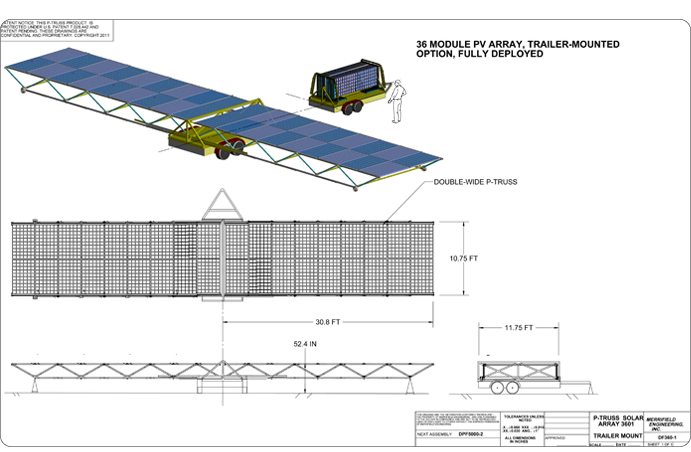

36 MODULE CONFIGURATION, TRAILER MOUNTED

The design layout below shows principal dimensions for a typical 36 module system, and uses a double-wide P-truss design. The iso views indicate how the 62 ft array is readily stowed on a 6 ft x 12 ft trailer body.

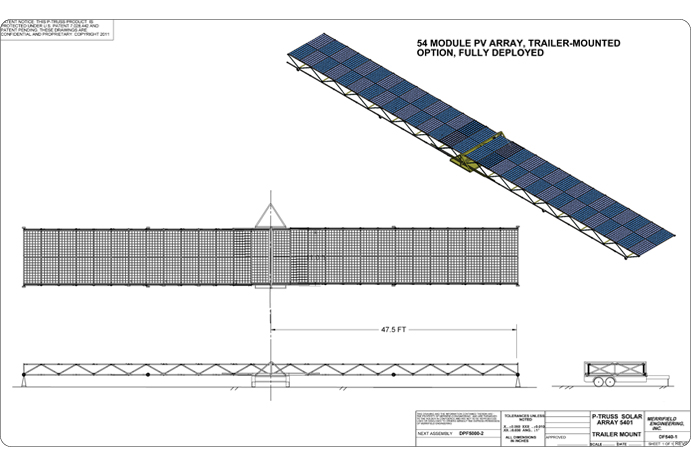

54 MODULE ARRAY, TRAILER MOUNT

This layout shows how the 36 module system is easily expanded by 50% to 54 modules. The twin PV arrays are 51 ft in length, but each retracts to 29 inches. The same size 6 x12 ft trailer bed is used.

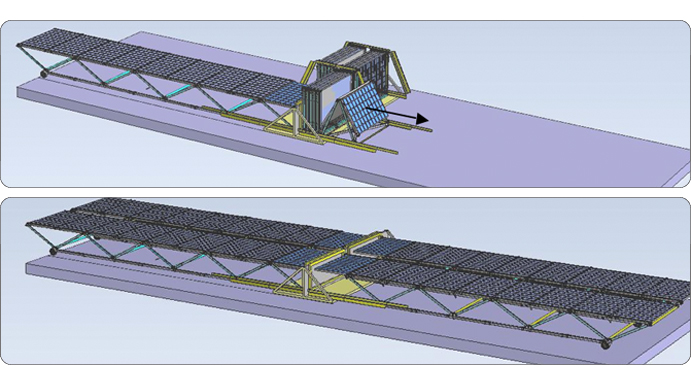

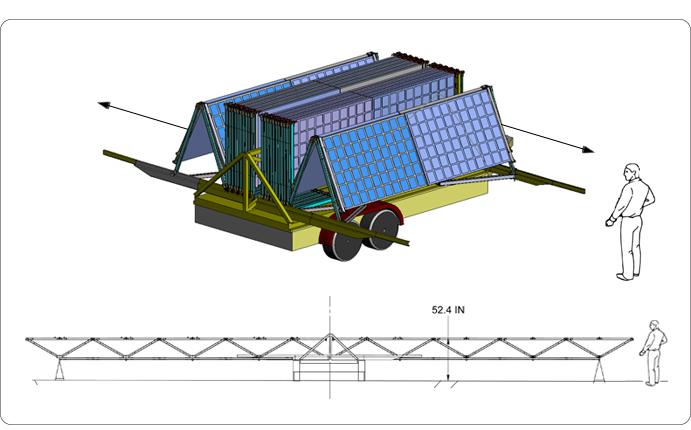

PV ARRAY DEPLOYMENT

This graphic illustrates the manner in which the truss-mounted PV modules are deployed from either a trailer mount or a ground pallet. The module interconnect wiring folds within the truss members. A simple wheeled dolly supports the first truss bay as the array is extended, after which end support stands are placed as shown in the drawing below. In the case of a pallet at ground level, end support wheels are used to support the array as it extends.

AVAILABILITY

Contact us for further technical information and for information regarding availability and licensing. We are glad to support applications engineering inquiries and happy to provide preliminary layouts and engineering information relative to configuration options, sizing, and design integration with specific trailers, pallet transporters and other application factors. >>More...

© 2014 Merrifield Engineering, Inc.