|

|

|

Technology & Applications Overview

E-truss represents a new class of deployable/folding truss structure characterized by modular construction, simplicity, and ability to retract axially (length-wise) into a compact unit with no loose parts . They have the characteristic high strength, low-weight and stiffness of conventional trusses. In summary the two major advantages which provide for an excellent cost/benefit ratio are:

• Quick deployment from a compact transportable package, and

• Ability to readily fold back into a compact state for ease of transport and stowage.

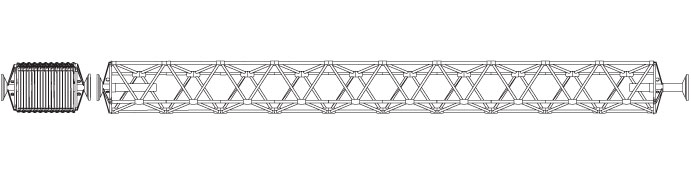

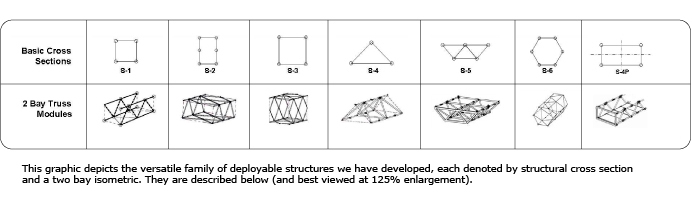

As a foldable structural system, its versatility comes from its modular nature and the availability of several cross sections - square, rectangular, triangular, trapezoidal, and hexagonal, including trusses that incorporate flat panels. Deployment, as a free module or an end-mounted extendible beam consists of expanding the truss axially (10x to 20x) until the folding chords lock and the structure becomes a load-carrying unit. This is typically done manually but can be power-driven.

HOW IT WORKS

GEOMETRIC CHARACTERIZATION

TRUSS DATA SHEETS

S-1 BASIC SQUARE SECTION

S-2 RECTANGULAR

S-3 SQUARE SECTION

S-4 TRIANGULAR

S-4P RECTANGULAR

S-5 TRAPEZOIDAL

S-6 HEXAGONAL

APPLICATIONS OVERVIEW

LOAD CAPACITY AND CONSTRUCTION

MANUFACTURING CONSIDERATIONS AND COST FACTORS

CURRENT DEVELOPMENT STATUS

INVESTORS AND LICENSING PATENT STATUS

HOW IT WORKS

The basic folding principal is that of "orthogonally-hinged" truss frames and joints, causing synchronous coordinated motion analogous to a scissor mechanism, except that unlike a scissor linkage, truss chords are formed to create a load-carrying truss structure. The joint axes always remain orthogonal to the truss axis producing the desired stable motion. (U.S. Patent 7,028,442 and patents pending)

GEOMETRIC CHARACTERIZATION

The following describes each truss structure by numbers of truss faces, internal diagonals, and chords.

| S-1 BASIC SQUARE SECTION | 3 OR 4 FACES | NO INTERNAL DIAGONALS | 4 CHORDS |

| S-2 RECTANGULAR SECTION | 4 FACES | NO INTERNAL DIAGONALS REQUIRED | 4 CHORDS |

| S-3 SQUARE SECTION | 4 FACES | NO INTERNAL DIAGONALS | 4 CHORDS |

| S-4 TRIANGULAR SECTION | 3 FACES | NO INTERNAL DIAGONALS NA | 3 CHORDS |

| S-5 TRAPEZOIDAL SECTION | 4 FACES | INTERNAL DIAGONALS | 5 CHORDS |

| S-6 HEXAGONAL SECTION | 6 FACES | NO INTERNAL DIAGONALS REQUIRED | 6 CHORDS |

| S-4P RECTANGULAR SECTION | 3 OR 4 FACES | INTERNAL DIAGONALS OPTIONAL | 4 CHORDS, PANELS OPTIONAL |

| S-1 BASIC SQUARE SECTION The S-1 represents the basic folding structure from which all the other trusses are derived in the E-truss/P-truss structural system. It comprises 3 planar trusses that are rigidly connected at common joints . It requires no internal bracing. In addition to its use as a beam or mast it is well-suited for work platform applications, forming floor and side rails. >>More |

|

|

|

S-3 SQUARE SECTION The S-3 is a closed square truss formed from two mated S-2 sections. Common chords and internal diagonals are omitted. All 4 sides have X-bracing. |

|

S-4 TRIANGULAR The S-4 triangular truss , patent pending, is also derived from the S-1 open section truss. Chords can fold internally using the patented orthogonal joints of the S-1 truss. Generally , it is well suited for masts and booms, and can form a curved profile. >>More |

|

S-4P RECTANGULAR Our new rectangular S-4P truss or P-truss, derived from the S-1, can deploy flat panels which fold compactly within the truss members. The panel edges are the folding chords. The panels fold and unfold in a "z-fold" pattern. Well-suited for solar PV panels, personnel platforms, and compact-stowage quick-deploy structural beams. When used as a personnel platform or bridge the floor panels do not have to be added separately. It can be configured as a beam or column/mast by using folding chords in lieu of panels. >>More |

|

S-5 TRAPEZOIDAL This truss, patent pending, combines two S-4 triangular trusses. A common center chord is formed. It is well-suited for area platforms, with decking panels added as required. >>More |

|

S-6 HEXAGONAL This truss has a hexagonal cross section and 6 chords, and is derived from the S-2 rectangular truss creating 6 faces at 120 deg angles. Generically it is used as beam, column, or enclosure frame for deployable habitats deployed quickly by crane or helicopter. |

|

APPLICATIONS OVERVIEW

This chart shows candidate applications by class or type and selected trusses by cross section. S-1,S-2, etc. To view application examples, click the links shown.

| CLASS/TYPE | APPLICATION | COMMENTS | E-TRUSS CANDIDATES |

| Work Platforms (Personnel) | Access Platform Scaffold Platform Service Platform Mast Climber |

Compact transport, stowage and rapid set-up. | S-1, S-2, S-4P |

| Bridging, Military and Civilian | Military Field Bridges Pipeline Bridges |

Rapid deploy, readily transported, few separate parts | S-1, S-2, S-4P |

| Portable Solar PV Arrays | Remote site power Disaster relief Military field power Electric vehicle charging Humanitarian assistance |

Compact transport and rapid set-up. Hybrid use with back-up generators (solar gensets) | S-4P |

| Event Platforms | Stages |

Rapid set-up and tear-down | S-1, S-2, S-4, S-5 |

| Disaster Relief Equipment | Solar panels, rapid-deploy infrastructure | For rapid deploy uses, Compact stowage for air/sea transport | S-1, S-2, S-4, S-4P |

| Folding Crane Booms | Crane Booms, Extensions, and Jibs (Incl. Tower Cranes) Lifting Fixture Strongbacks |

Military use, compact for air transport For self-erecting tower cranes Compact, adjustable |

S-2, S-4, S-4P |

| Towers | Communication Towers Lighting Towers |

For rapid deploy uses, disasters and military | S-1, S-2, S-4P |

| Mobile Equipment (Truck/Trailer Mounted) |

Antennas |

For military use and disaster relief Jobsite cost savings from quick deploy Compact unit for aircraft personnel access Compact tractor booms for ease of handling |

S-1, S-2, S-4P |

| Marine | Floating Docks for Piers Ship Gangways & Ladders Floating Bridges |

With air bladders for ease of extension/retraction Compact folding self contained gangway Military quick deploy bridge supports |

S-2, S-4P, S-5 |

| Space (Orbital/Surface) | Space Platforms and Beams/Masts Space Vehicle Structures Surface Platforms (Lunar) Surface Transporters Construction Equipment |

Contact us for information | S-2, S-4P, S-5, S-6 |

| Compact Rescue Equipment | Personnel Basket |

Quick deploy, stowable Emergency ladder extension |

S-4P |

MANUFACTURING CONSIDERATIONS AND COST FACTORS

|

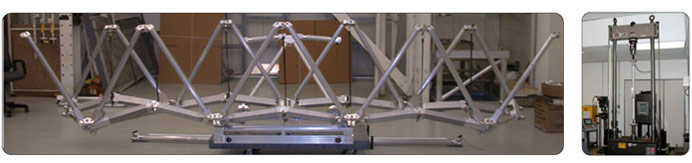

(The above photo and the two below where taken at NASA-KSC.) |

DEVELOPMENT STATUS

|

|

Using this database, we have created configurations and design options for a large number of applications. A number of such applications are illustrated and described in this website. Our technology is currently protected by a primary U.S. patent, with three U.S. patents pending.

Our industrial co-developer, United Space Alliance, has an extensive database of hardware drawings, CAD models, structural and dynamic models. They maintain development-level truss assemblies, components, test fixtures, and instrumentation. A 21 ft Platform for critical servicing of flight vehicles has been thoroughly analyzed and tested under service conditions.

To date, we have jointly tested several configurations of the S-1 and S-2 trusses as deployable platforms & towers. Formal structural testing was performed on end-supported, cantilever-mounted and base-mounted/ center-mounted configurations, along with weld testing and component load/deflection testing. This has included special mounting platforms, preloaded joint testing, and a limited degree of powered actuation testing.

We can offer validated design concepts within our multi-truss system of modular structures as described earlier in our website, and we continue to evaluate new truss designs, components, and applications for industrial, commercial, military, disaster-relief, marine, and aerospace markets.

INVESTORS AND PATENT LICENSING

Merrifield Engineering welcomes discussions with interested investors regarding shares of company ownership, either participating or non-participating. Our extensive offering of truss designs for industrial, commercial, military, marine, and aerospace applications is expected to result in several manufacturing lines and special custom product lines over the next five years. We are particularly interested in partnering with manufacturing companies with related capabilities , and with user companies wishing to expand their product offerings. For interested companies this new structural system can provide a competitive edge through offering of innovative new compact folding structures.

Our intellectual property interests now include the E-truss (Extendible truss) base patent U.S. 7,028,442, P-truss (Panel truss, S-4P) patent pending, S-2 Rectangular patent being issued, and S-4 triangular patent issue expected late 2010. We are ready to discuss licensing opportunities and terms at any time.

© 2014 Merrifield Engineering, Inc.